You can find technical information about our products on this page.

Product Features

- MATERIAL: Manufactured from polyester, fiberglass and stone dust.

- TEXTURE: It gives an identical stone appearance with its look and texture.

- WEIGHT/THICKNESS: It has a 5-8 kg/m2 average weight and a 3-5 cm thickness

- SIZE: The product size is usually 133 × 285 cm, however, it can vary a few centimetres depending on the model.

- UV resistance: It is absolutely not affected by ultraviolet rays.

- IMPACT RESISTANCE: It is highly resistant against impacts thanks to its shock absorption feature.

- WATER AND MOISTURE RESISTANCE: It is not affected by water and moisture. It can be easily used in places such as kitchens and bathrooms. It can be easily used in places such as kitchens and bathrooms.

- SIZING: It can be easily cut via decoupage or a diamond saw. It can be used in the places where get intense sunlight or heat exposure.

- SIZING: It can be easily cut via decoupage or a diamond saw.

- APPLICATION: It can be easily applied to all surfaces which its rough construction is completed with screws and dowels.

- CLEANING / MAINTENANCE: It is washable and wipeable. It does not require extra care.

- FLEXIBILITY: Oval and moving forms can be given thanks to its flexible structure.

- CHROMATICITY: It can be painted easily to the desired color.

- CONTINUITY OF PATTERN: Thanks to that all models have pattern continuity, a natural look is obtained on the applied surface.

- ENVIRONMENTAL SENSITIVITY: It doesn’t contain any carcinogenic substances and any substance that is deleterious to health. It is environmentally friendly.

Advantages

- Can be easily applied to all surfaces which its rough construction is completed.

- Eliminates the paint and insulation costs.

- Can be conveniently used indoors and outdoors. It is certainly not affected by external factors such as rain, sun, heat etc. It gives a feeling like a real stone when touched.

- it eliminates problems such as regional loss and joint gaps which occur in natural stone applications.

- It can be applied to the structures such as vault, arch thanks to its flexible structure, and the fireplaces and columns can be covered with it.

- Thanks to its flexible structure, it can be applied to areas such as vaults, arches, fireplaces and columns can be covered.

- Can be easily cut and drilled. Decorative materials can be hung on the coated surface.

- Can be easily cut and drilled. Decorative materials can be hung on the coated surface.

- It can be applied as portable for decoration design in the store windows and exhibition stands.

- It makes no harm to the places it mounted on except the screw holes.

- Eliminates construction dirt such as cement, plaster, sand etc.

- It can be resized after removal and applied to another place thanks to its easy disassembly feature.

- It doesn’t require building and construction permits.

- It is more practical, lightweight, durable and useful than natural stone applications.

Measurement Results

| TECHNICAL DETAIL | STANDARD | UNIT | VALUE |

|---|---|---|---|

| Tensile strength | ISO 527 | MP3 | 39 |

| Elastik-modülü – çekme | ISO 527 | MPa | 5246 |

| Tensile elongation | ISO 527 | MPa | 1,81 |

| Bending strength | ISO 178 | MPa | 157 |

| Elastik-modülü – eğilme | ISO 178 | MPa | 7030 |

| Bending elongation | ISO 178 | % | 4,87 |

| Izod impact strength | ISO 180 | kj/m2 | 55 |

| Lol-limit oxygen index | ISO 4586 | % | 26 |

| Barkol | ASTM D-2583 Co | 48 |

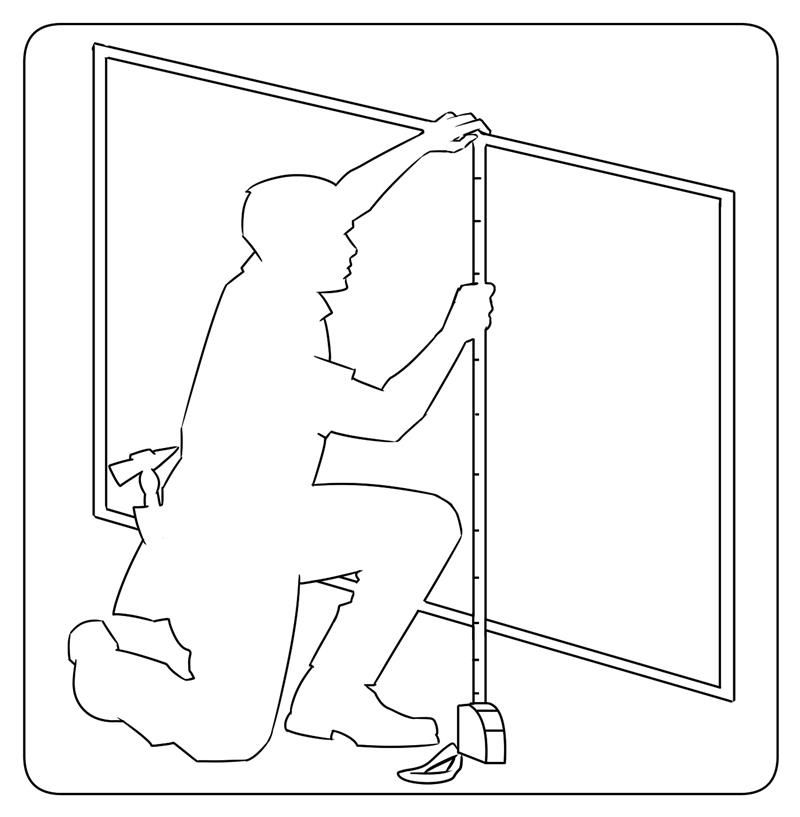

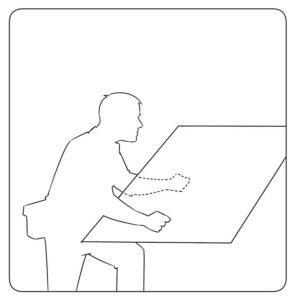

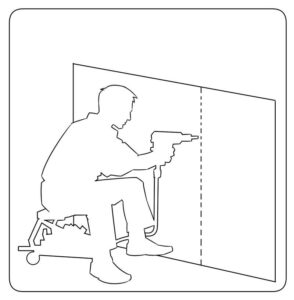

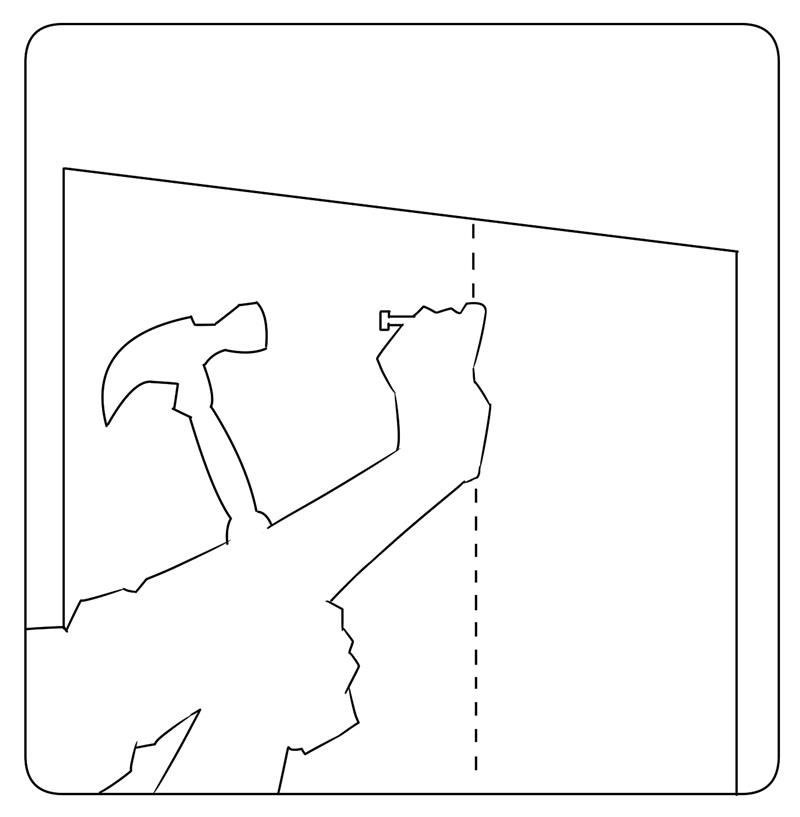

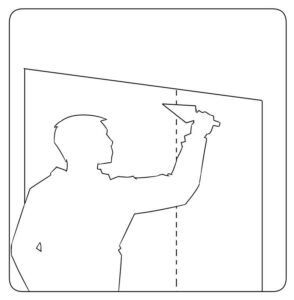

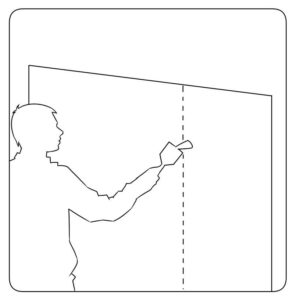

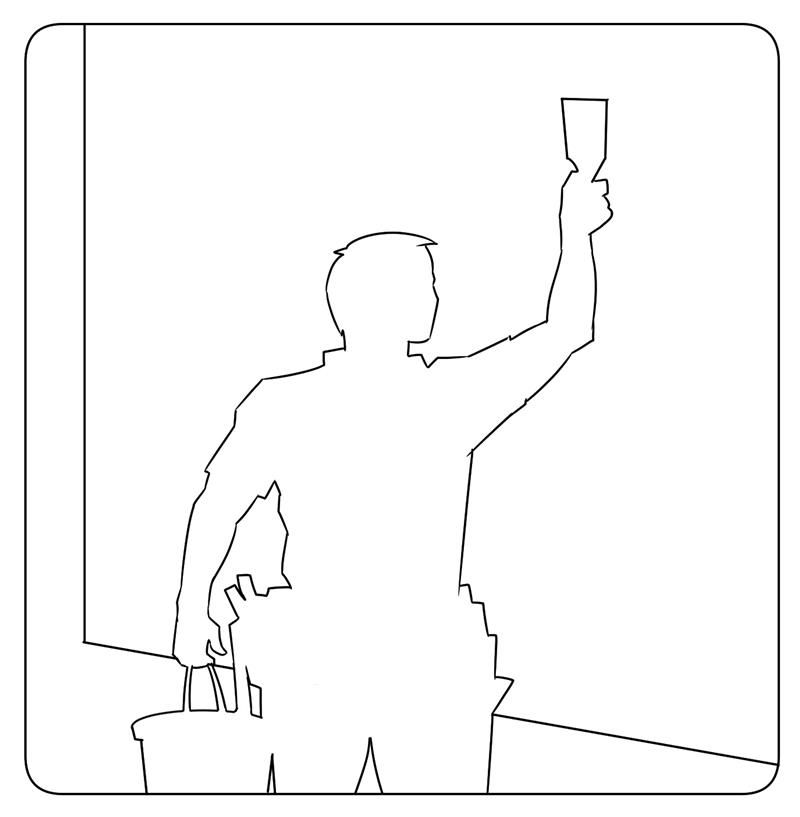

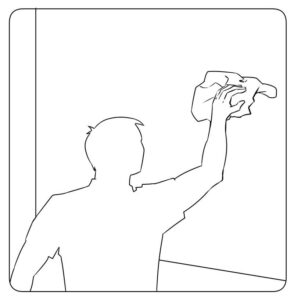

Installation Guide

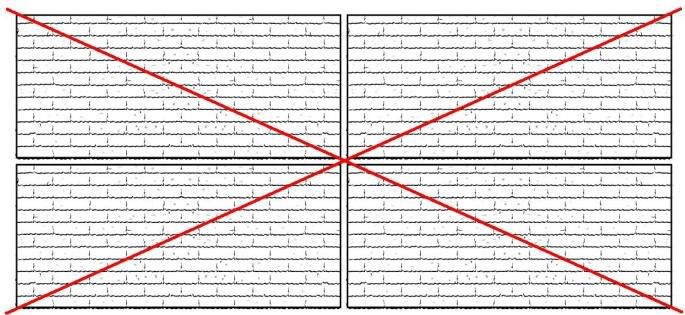

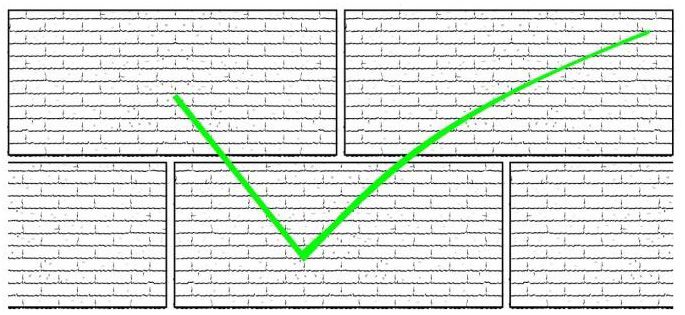

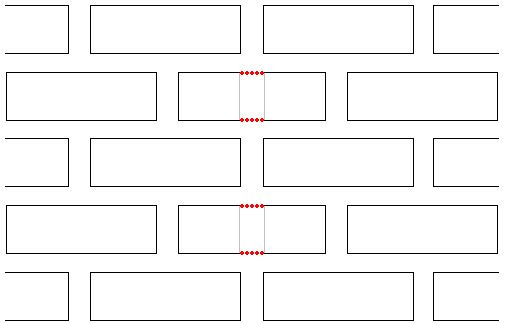

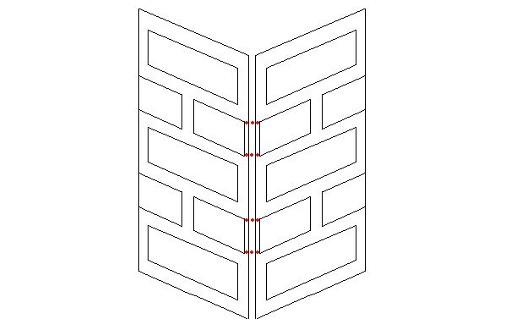

Your DC panels must be applied to the surface not in a regular fashion (Figure 1) but in an irregular fashion (Figure 2). This way, vertical joints will not become aligned and you will not have repetitive textures in the same area. Figure 1 Figure 2 At vertical joints of your DC panel (in brick models), gaps between half-cut bricks must be filled with DC Mastic, while joints must be formed between full-sized bricks without any filling (Figure 3). n the stone models, stones similar in size must be combined by way of filling while there must be a joint in between differently-sized stones. Similarly, half-cut bricks must be merged and brushed into a corner in places where edges of two panels form a corner (Figure 4). Figure 3 Figure 4 Before using the retouching brush, you must make sure that areas applied with mastic have completely dried. Otherwise, paint may bleed after several days, causing color tone differences at joints. While applying the mastic, you can prevent lumping by continuously cleaning your brush with the cleaning products supplied to you. Measure the installation area. Cut the panels using spiral diamond saw. Place the panel on the application surface and make holes using a power drill. Place the panel on the application surface and make holes using a power drill. Fix panels to surface with screws and hammer. Use an average of 20 screws for each panel. Cover joints and screw holes by filling with DC Mastic using a spatula. Spread mastic with help of brush. Paint joints and screw holes with a matching color paint. Finally, wipe the surface clean with a piece of cloth or a sponge. Installation is complete. You can now enjoy your new DC Panel!